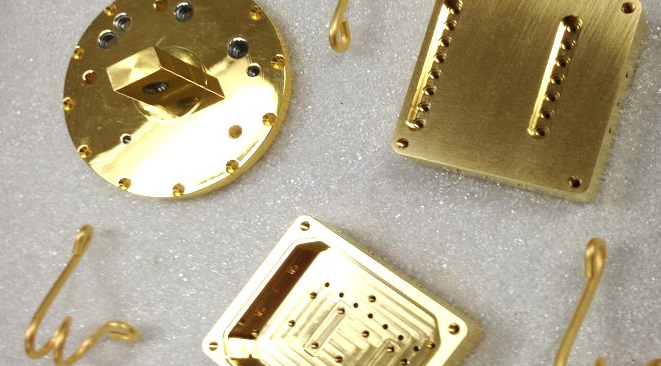

Gold Plating

Gold Electroplating is a method of depositing a thin layer of gold onto the surface of another metal. Gold plating finds its uses in jewelry, semiconductor industry. It often requires that the substrate be cleaned and etched before it can be electroplated with gold.

Gold plating solution is made by dissolving an appropriate amount of gold salt into water or other solvent. The solution may contain additives such as cyanide ion (CN) to prevent oxidation of the gold during the plating process.

Gold Plating Solutions

Gold plating solutions are usually classified according to their composition:

Cyanide-free solutions: These solutions do not use cyanide ions to stabilize the gold deposits. They typically have higher concentrations of gold than cyanide-containing solutions. However, they tend to be more expensive because of the cost of the gold salts used.

Cyanide-based solutions: These electroplating gold solution contain cyanide ions to stabilize gold deposits. In addition, these solutions also include stabilizing agents such as thiourea dioxide (TUO2).

The most common cyanide-based solutions are:

Au/Ag/Cu/Pd/Ni/Co/Zn/Fe/Al/Cr/Mg/Ca/Si/Sr/Ba/K/Na/Li/Ti/Sn/Hg/Pb/Bi/Se/Te/As/Sb/Mo/W/Re/Ta/Nb/V/Sc/Y/La/Lu/Hf/Ta/W/Os/Ir/Rh/Pt/Au/Th/Pa/U/Np/Pm/Am/Cm/Bk/Rn/Ra/Ac/Fr/Ds/Ce/Pr/Nd/Sm/Eu/Gd/Tb/Dy/Ho/Er/Tm/Yb/Lu/Hf/

In general, gold plating solutions are prepared using either a batchwise or continuous mode of operation. Batchwise preparation involves mixing all components together at one time and then adding them to the tank containing the substrate being plated. Continuous preparation involves adding each component separately to the tank containing the substrates. For example, U.S. Pat. No. 5,912,093 discloses a continuous preparation of gold plating solution.

In order to obtain high quality gold plating, it is important to control the concentration of the gold salt in the plating bath. This is especially true when the plating bath contains cyanide ions. Cyanide ions react with gold to form insoluble complexes which precipitate out of the gold electroplating solution. If the concentration of the gold is too low, the gold will not deposit properly. On the other hand, if the concentration of the gold exceeds the solubility limit for the gold salt, the excess gold will remain dissolved in the solution rather than forming a stable complex. Thus, the gold plating solution must be carefully monitored to ensure proper deposition of the desired thickness of gold on the substrate.

One way to monitor the concentration of gold in the plating bath is to measure the conductivity of the electroplating gold solution. Conductivity measurements provide information about the concentration of gold in a sample of the plating solution. However, this approach has several drawbacks. First, the conductivity measurement only provides information about the total concentration of gold in the solution. It does not indicate whether the gold is present in the free state or in a complexed state.

Second, the conductivity measurement is based on Faraday’s law of electrolysis, which states that the current flow through an electrical conductor is proportional to the number of electrons flowing through the conductor per unit time. The Faraday’s law of electrolysis applies to the case where there is no charge transfer between the electrodes of the cell. However, in the case of a gold plating solution, the gold ions can change their valence from +1 to −1 during the electrochemical reaction. Therefore, the current measured by the conductivity meter may not accurately reflect the actual amount of gold deposited on the substrate.

Another method used to determine the concentration of gold in plating baths is atomic absorption spectroscopy (AAS). AAS measures the absorbance of light at a particular wavelength corresponding to the characteristic emission spectrum of the element under investigation. When the element absorbs light energy, it emits photons having energies equal to the difference between the energy of the absorbed photon and the ground state energy of the atom. By measuring the intensity of the emitted radiation, the concentration of the element in the solution can be determined. One drawback of AAS is that it requires expensive equipment and trained personnel to operate the instrument. Also, AAS cannot distinguish between different types of gold compounds such as Au(I) and Au(III).