Understanding the Cost of Metal Coatings: A Practical Guide

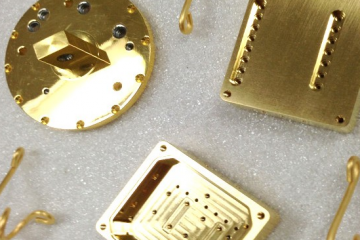

When selecting a metal coating for your application, cost is always an important factor. While it might be tempting to choose the least expensive option, it’s critical to understand the trade-offs in durability, performance, and long-term value. Here, we explore how the cost of different coating types compares, particularly focusing on our PEN-TUF® process—electroless nickel with PTFE. Relative Coating Costs There are many effective solutions for environments that require corrosion protection and where the parts are not subject to abrasion. They are relatively low in cost but are often quite effective. Examples include: As performance requirements increase, so does the need for a higher quality coating. For maximum corrosion protection and superior electrical conductivity, precious metal plating is often the best option: Of course, precious metal plating can be costly, especially since gold is currently trading at over $3,000 per troy ounce. PEN-TUF® Pen-Tuf Pentuf® is an electroless nickel plating Read more…