Electroless Nickel Plating. A Versatile Plating Application

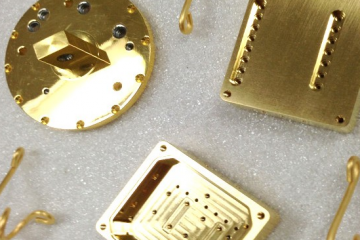

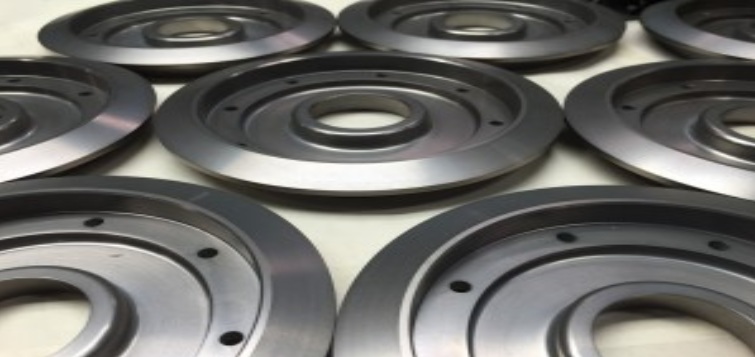

Precision and Dimensional Control

Electroless nickel is often referred to as an engineering coating due to its exceptional precision. It allows for tight control over thickness, making it suitable for high-tolerance applications. Typical coating thicknesses range from 0.001” to 0.002”, with tolerances as close as ±0.0001”.

This precision makes electroless nickel ideal for:

- Close-Tolerance Fittings – Ensures a perfect fit for precision parts

- Uniform coating thickness regardless of part size – Large or small parts can be uniformly coated. AST has tanks that can process parts up to 60” x 60” x 24”

Pen-Tuf® & BNEN Electroless Nickel

Ultimate Solutions for Wear & Friction

What is Pen-Tuf®? Electroless Nickel Plating with PTFE

Pen-Tuf® is Electroless nickel plating with PTFE. It combines the hardness of nickel with the low friction properties of polytetrafluoroethylene (PTFE). This unique combination results in a coating that provides both wear resistance and solid lubricity, making it ideal for a wide range of applications where metal-to-metal contact occurs.

What is BNEN? Electroless Nickel Plating with Boron-nitride

Similar to Pen-Tuf®, BNEN provides solid lubricity with a low coefficient of friction. It is very hard, around HRC 65, and highly heat resistant.

Unlike liquid lubrication (like the oil in your car), both Pen-Tuf® and BNEN provide solid lubricity where the coating itself has a low coefficient of friction. This provides consistent anti-galling, reduced stiction, and improved part-to-part sliding performance without the need for additional lubrication.

Applications for Pen-Tuf®

PEN-TUF® is used in various industries and applications where reducing friction and wear is critical. Some common uses include:

- Internal Gun Parts – Provides longer life and reduced friction for sliding or rotating components

- Rotating Shafts and Bearings – Reduces wear in high-friction environments

- Reciprocating Motors and Machinery – Ideal for applications like saber saws, where metal parts move against each other at high speeds

- Aircraft Pneumatic and Hydraulic Systems – Ensures parts last through expected cycles with fail-safe performance

Case Study: Aerospace Fasteners

One notable application involved specialized lock washers for an aerospace company. These washers needed to maintain position without unintended movement while also being easy to remove during maintenance. PEN-TUF®’s solid lubricity provided the perfect balance, ensuring reliability and ease of maintenance in critical aerospace applications.

Comparing Pen-Tuf® to BNEN

While PEN-TUF® offers excellent wear resistance and BNEN is an alternative that provides even greater hardness. However, there is no military or industrial specification for boron nitride electroless nickel, limiting its use in aerospace and defense. PEN-TUF®, on the other hand, is widely accepted and specified for military and industrial applications.

Key Differences:

- PEN-TUF® (Electroless Nickel with PTFE) – conforms with AMS 2454, providing excellent lubricity, Rockwell C 40-45, moderate temperature resistance.

- Boron Nitride Electroless Nickel – Superior hardness, comparable to hard chrome (Rockwell C 65-68), excellent lubricity, higher temperature resistance. Lacks an industry specification

The Bottom Line

Electroless nickel plating offers an unmatched combination of dimensional control, wear resistance, lubricity, and precision. Whether you need a solution for high-friction machinery, aerospace components, or commercial applications, PEN-TUF® and BNEN are superior solutions.

Contact us today to learn how PEN-TUF® or BNEN can enhance the performance and lifespan of your components.