Boron Nitride Electroless Nickel

Boron Nitride Electroless Nickel (BNEN) plating service provides a composite deposition of Electroless Nickel and Boron Nitride particles. This plating is one of our advanced composite plating operations ideal for parts that require both hardness as well as lubricity. Deposit Benefits include exceptionally low coefficient of friction, superior release and excellent wear resistance. BNEN can be coated to thicknesses ranging from .00005-.002 inches. Unlike EN-PTFE, EN Boron Nitride deposits can be heat treated to attain maximum hardness for very severe wear applications. Advanced Surface Technologies can deposit the Electroless Nickel with Boron Nitride on Aluminum, Copper, Brass, Magnesium, Stainless Steel and Steel. Deposit characteristics include:

- Physical appearance Matte

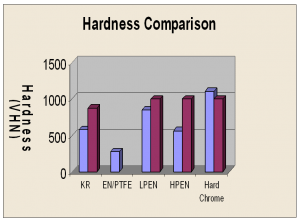

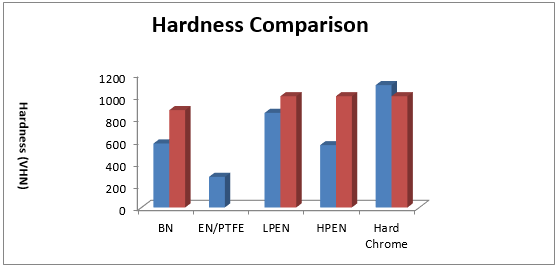

- Hardness (VHN/) (as plated) 550

- ( heat treated @ 400º C/1 hr) 850

- Melting range º C ( º F) 880-1200 ( 1620-2190)

- Magnetic Properties magnetic

- 6-8% b.w (15-20% b.v) BN particles in the deposit

- Uniform Deposit

- Heat treatable

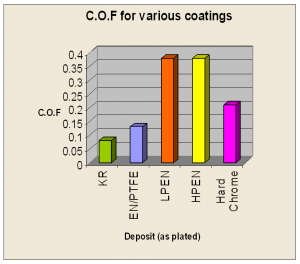

- Lowest COF of all composites tested

- COF decreases with increasing load

- Unlike PTFE, BN is very hard and resistant to temperatures up to 1200°C

- Uniform particle distribution

- Numerous wear and low COF applications

- Reduces wear on valuable tools, equipment, etc.

- Improve release properties of molds and dies

- Eliminates liquid lubricants

- Reduces galling

- Noise reduction

- Uniform, no post plate grinding

- Superior protection against wear

- No reduction in fatigue strength of substrates

- Allows use of lighter substrates

Advanced Plating Composites for Mission-Critical Applications

For applications requiring exceptionally low friction coefficients, superior release capabilities, high abrasion resistance, and the ability to withstand high temperatures, Boron Nitride Electroless Nickel (BNEN) plating is among the most advanced coating options in the industry.

This advanced plating composite is created by suspending Boron Nitride particles in a medium-phosphorus Electroless Nickel deposit. AST’s process produces one of the highest degrees of hardness, while providing exceptional lubricity.

Boron Nitride Electroless Nickel Plating is Engineered for Performance

BNEN is a synthetic compound, precision-engineered to solve multiple problems simultaneously. The Boron Nitride particles are Second in hardness only to natural diamond, it’s ideal for coating complex, critical internal moving parts such as hub assemblies for the automobile industry, landing gear components for the defense and aerospace industries, or ball valve assemblies in the oil and gas extraction field.

Regarding thermal and chemical stability, BNEN is capable of withstanding temperatures of up to 1700 degrees fahrenheit. In addition, it possesses such a low friction coefficient that it may be used in applications requiring the lubricity of PTFE, and the hardness to withstand increased wear under heavy loads. This advanced plating composite may be heat treated for improved hardness as well.

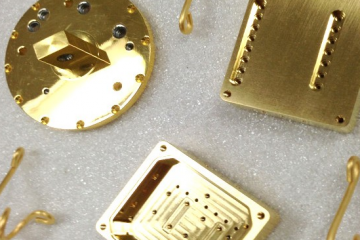

The deposit is matte in appearance; thickness ranges from .00005-.002 inches, and is exceptionally uniform, requiring no post-plate grinding.

Preserve valuable equipment through reduced wear, improve mold and die release properties, eliminate liquid lubricants, achieve significant noise and weight reduction, and more. Some of the world’s leading aerospace, automotive, extraction, and electronics companies rely on AST for high quality, on-time custom plating solutions.

Over 40 Years of Custom Plating Solutions

Advanced Surface Technologies provides the highest quality BNEN plating services available for coating Aluminum, Copper, Brass, Magnesium, Stainless Steel and Steel with no reduction in the fatigue strength of these substrates.

A Leader in Boron Nitride Electroless Nickel Plating

- One of the largest metal plating operations in the region

- In-house lab facilities with 8 substrate-specific process lines

- Recipient of the Colorado Environmental Leadership Award for innovative hazardous waste recycling programs

- On Time Every Time Delivery pledge

- Meets virtually any requirement for BNEN plating

Call us today for high quality, price competitive, responsive turnaround surface plating services, and allow us to exceed your expectations.